Reflect® Implant Systems offer surgical and prosthetic compatibility

as well as uncompromised quality and performance.

Reflect Implants have been tested to demonstrate their strength and ability to withstand long-term functional loading. These tests validate that Reflect Implants are comparable to the original, assuring long-term reliability when placed under functional loading as well as compatible with surgical kits and common connection prosthetics.

Uncompromised quality and performance for better patient outcomes.

Compatible.

Reflect® Implant Systems offer surgical and prosthetic compatibility with major implant brands, but do so at a fraction of the cost while at the same time, offering uncompromising quality and performance.

Strong.

Manufactured from our Grade 23 ELI Titanium Alloy, they provide greater strength when compared to implants manufactured with conventional Grade 4 Titanium.

Tested and Reliable.

Reflect Implants have been tested to demonstrate their strength and ability to withstand long-term functional loading. These tests validate that Reflect Implants assure long-term reliability when placed under functional loading. And they are compatible with surgical kits and common connection prosthetics.

Innovative.

Reflect Implants are manufactured with a state-of-the-art S-L-A surface treatment procedure that creates macro, micro, and nano surface structures that enhance the bone to implant contact (BIC). This surface treatment has been established as the “gold standard” of the dental implant industry. The sand-blasting, acid etching, and extensive cleaning of the Reflect (S-L-A) surface achieve desired morphology for osseointegration.

Reflect® Implant Systems offer surgical and prosthetic compatibility with major implant brands, but do so at a fraction of the cost while at the same time, offering uncompromising quality and performance.

Strong.

Manufactured from our Grade 23 ELI Titanium Alloy, they provide greater strength when compared to implants manufactured with conventional Grade 4 Titanium.

Tested and Reliable.

Reflect Implants have been tested to demonstrate their strength and ability to withstand long-term functional loading. These tests validate that Reflect Implants assure long-term reliability when placed under functional loading. And they are compatible with surgical kits and common connection prosthetics.

Innovative.

Reflect Implants are manufactured with a state-of-the-art S-L-A surface treatment procedure that creates macro, micro, and nano surface structures that enhance the bone to implant contact (BIC). This surface treatment has been established as the “gold standard” of the dental implant industry. The sand-blasting, acid etching, and extensive cleaning of the Reflect (S-L-A) surface achieve desired morphology for osseointegration.

S-L-A surface treatment provides better bone-to-implant contact

Reflect Implants are manufactured with a state-of-the-art S-L-A surface treatment procedure that creates macro, micro, and nano surface structures that enhance the bone to implant contact (BIC). This surface treatment has been established as the “gold standard” of the dental implant industry. The sand-blasting, acid etching, and extensive cleaning of the Reflect (S-L-A) surface achieve desired morphology for osseointegration.

Packaging

Reflect Implants’ multi-stage extensive cleaning process removes residues and yields a contamination-free surface. That surface is then protected from contamination by packaging in a Titanium sleeve. This ensures that the implant is only in contact with Titanium until you remove it for surgical placement.

Clinicians can be confident they are providing patients with one of the highest quality precision-manufactured dental implant systems and at a lower price point.

Clinicians can be confident they are providing patients with one of the highest quality precision-manufactured dental implant systems and at a lower price point.

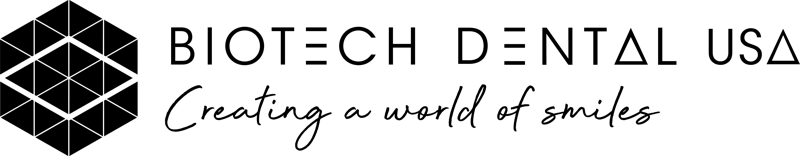

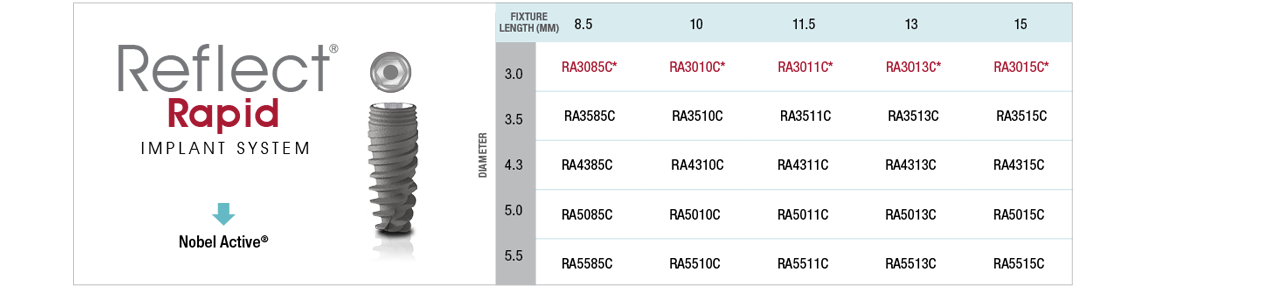

Compatible with Top Brands

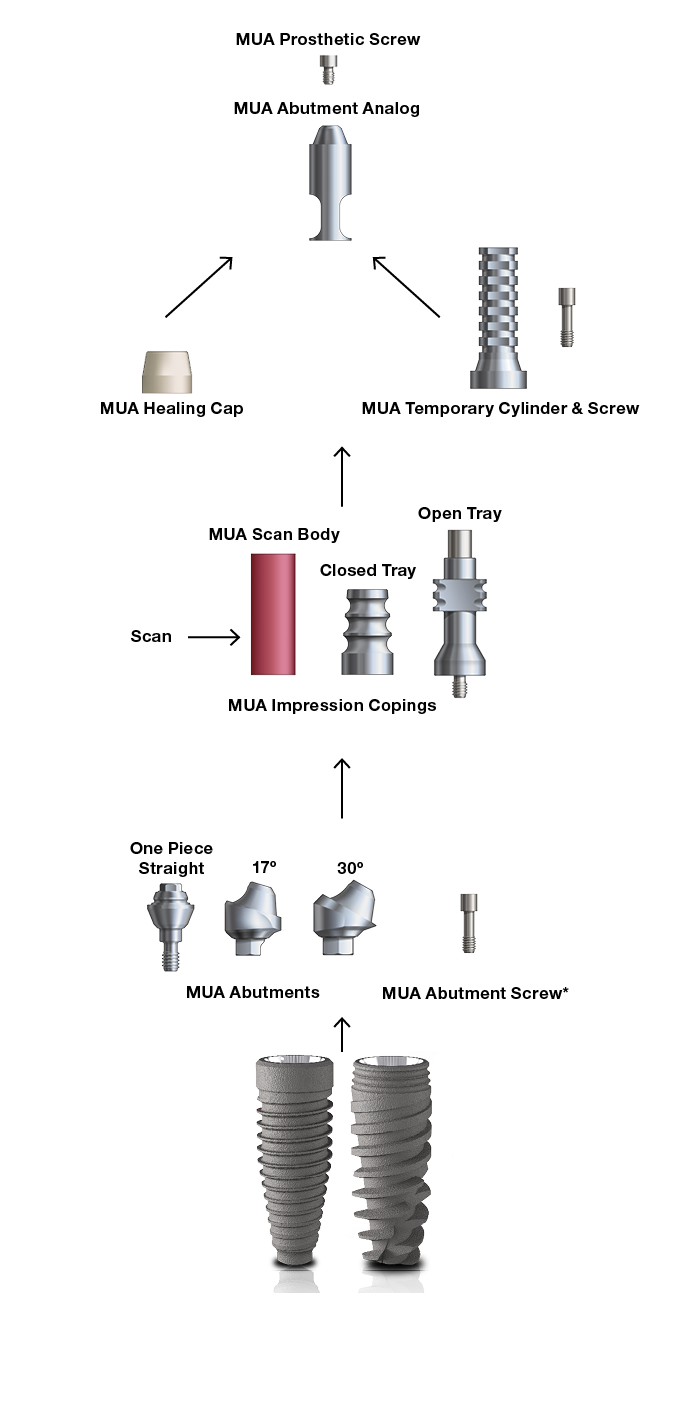

REFLECT PROSTHETICS

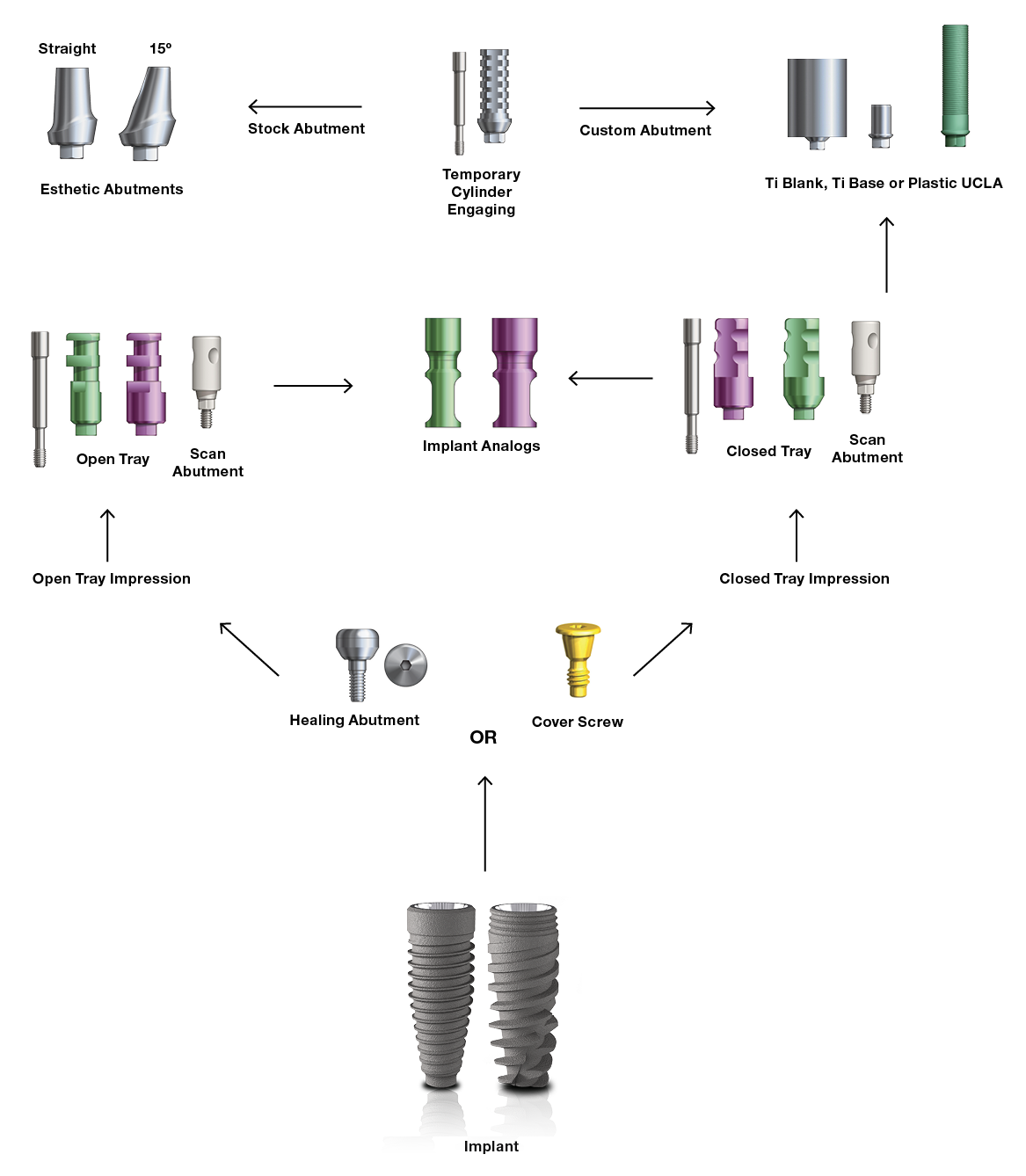

SINGLE UNIT FLOW CHART

MULTI UNIT FLOW CHART